The quality of pet treats changed with the conception of Loyalty Pet Treats and our exclusive patented Nutrieseal® process.

We are a Manufacturer of high quality, aromatic, pure natural treat that is the closest to raw that had never been seen or experienced by any pet lover, owner, dog trainer or industry person.

The Benefits of Nutrieseal®

- Up to 50% cheaper than freeze dried products

- Superior or equal in nutrition compared to freeze dried

- Superior to air drying

- Superior to oven drying/baked

- Superior in flavour, intensified through the Nutrieseal® process

- A strong & pleasant aroma

- Shelf stable product, no refrigeration required

- Effectively neutralising harmful bacteria

- We don’t just extract moisture, we intensify the product.

Nutrieseal® technology ensures minimal interference with the raw product, producing a natural treat full of flavour, colour & nutrition.

When dehydrating meats all care needs to be taken into the final stability and nutritional quality of the product.

Water Activity is a critical factor in how your product can remain stable and avoid mould and fungal growth.

If you extract too much moisture you can make the product very light in weight and more expensive. If you do not extract enough moisture your product remains unstable and susceptible to mould and fungal growth as well as any bacteria that was not dealt with through pasteurisation.

Pasteurisation is a critical factor in controlling bacteria in your product.

Heating the product too long will just denature the product, you may as well feed your pets cooked meats as most of the benefits for your pets will not be there. Not giving the product enough time under pasteurisation temperatures leaves the product vulnerable to bacteria that have not been dealt with. Finding the balance between the two is tantamount to a healthy shelf stable treat. This is where the Nutrieseal® process comes into its own. Let us try to explain this for you.

How Nutrieseal® works

- Loyalty Pet Treats is the only pet treat manufacturing company in the world with its unique advanced dehydration technology. Using refrigeration, coupled with our patented Nutrieseal® system, we produce premium quality treats every time.

- The Nutrieseal® system is designed for dehydrating food products: meats, fish, poultry, vegetables and fruit at low temperatures.

- Product is loaded into a hermetically sealed chamber with no outside influences. Our Nutrieseal® system sends a controlled airflow of continuously purified air over the product extracting the moisture (we work in reverse we suck the moisture out others blow hot air). The purified air kills airborne bacteria as well as bacteria on the surface of the food and process equipment.

- Temperature profiles during dehydration are varied according to product characteristics and to perform pasteurisation at two key times. Duration of the pasteurisation cycles are varied to ensure the required temperatures are achieved throughout the mass of the food product. Total drying time varies according to product characteristics and is typically in the range of 36 hours to 55 hours.

- The automated low temperature control system monitors the temperatures throughout the whole process, varying it so as not to denature or destroy the proteins, nutrition, flavour or aroma of the product.

- The low temperature moisture extraction and the re-circulation of the drying air retains the maximum amount of flavours and aroma in the food and has the minimum effect/degradation of organics/nutrients within the food structure.

- The result of this is the high-quality finished products of Loyalty Pet Treats.

Nutrieseal® compared to other Pet Treats Processes

Other forms of drying are effective to a point & no doubt you will hear the virtues of one over the other, but in simplistic terms, this is a break down for you.

Freeze Drying

- Freeze-drying is NOT a food safety practice.

- It does NOT kill bacteria

- All manufacturers of Freeze Drying machinery advise that meat & seafood should be cooked before drying. This is to deal with any bacterial issues that are inherent in all raw meats.

Freeze drying food uses a process called lyophilisation to lower the temperature of the product to below freezing. Then a high-pressure vacuum is applied to extract the water in the form of vapour. The vapour collects on a condenser, turns back to ice and is removed. Finally, a gradual temperature rise extracts all remaining ‘bound’ moisture from the product. This process retains the physical structure of the food product and preserves it for re-hydration at a later date.Precisely the same process for Freeze Drying Pharmaceuticals & Biologicals such as Vaccines & antibodies, penicillin, viruses & bacteria.

Freeze drying is used in Research Laboratories around the world. The reason for this is, you can dry all forms of bacteria and virus and put them in a point of stasis and store them for long periods of time. When thawed out and exposed to ambient temperatures all the virus and bacteria are reactivated back to where they were. The issue on any freeze-dried pet products, all the talk is about how they dry and preserve the product, but nothing as to how they deal with the bacteria. Most treatments will involve a heat treatment at some stage to pasteurise the product to destroy bacteria, you don’t see that on any sites, so not sure about the products stability once packet is opened or moisture is added.

Heat/Air Drying

- Reduces nutritional value and flavour

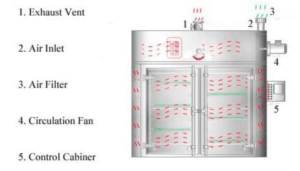

Product is loaded into a dryer; fans draw in fresh air, distribute it evenly over the product, and expel it through a discharge vent. Standard units operate from ambient up to 120 °C, modulating valves also enable the flow of air through the cabinet to be varied and the operating temperature can be adjusted up to 200°C.

Anything over 70c for long periods is actually cooking your meat dry, so 120c – 200c is definitely denaturing your product by cooking dry and destroying any nutritional benefits.

Air drying involves sourcing air from outside, so if filters are clogged or dirty, if it is raining or very humid!!!! These are elements that influence how your products dry, the length of time it takes to dry & the quality of the finished product.

The final result from this process is, you should have a product that has dealt with bacterial issues, but in the process has reduced nutritional values and flavour.

Extruded “shaped” treats

- Denaturation of proteins

- Simplification of complex starches, increasing rates of tooth decay

- Reduction of microorganisms in the final product

- Slight increase of iron-bioavailability

- Creation of insulin-desensitizing starches (a potential risk-factor fordeveloping diabetes)

- Loss of lysine, an essential amino acid necessary for developmental growthand nitrogen management

- Increase of glycemic index of the processed food, as the “extrusion processsignificantly increased the availability of carbohydrates for digestion”

- Destruction of Vitamin A (beta-carotene)

Extrusion is a high heat and pressure process that pushes the ingredients through a metal die with holes cut for the blended mixture to pass through. For kibble it “puffs” the ingredients into kibble bits after which they’re sprayed with a “tasty” coating to make them more appealing to your dog.

Conclusion

After 18+ years of being a Safe Food Queensland accredited manufacturing facility specialising in Ultra-premium pet treat manufacturing, we have seen, heard, and read some fantastic stories about the different forms of creating a dried pet treat. So much of it is not true. It is frightening. Unfortunately, people can only be educated by what they see or read, and misinformation is dangerous.

To read comments like “Air dried treats are laid out in a sterile environment where the air is circulated to initiate a drying process. This means that there is absolutely no heat involved”.

Really! If there is no pasteurisation, this process is as bad as freeze drying as there is no way to kill the bacteria. Freeze drying ” The greatest form of drying around!” For fruits & yoghurts. If you are talking about any products that need to deal with bacteria for food safety! A big fail! It was unstable raw & is unstable when dried this way. That is why their advice is to cook the meats before drying or rehydrate & cook after drying.

- Heat/Air Drying This process will deal with bacteria, but the constant high heat takes away nutrition & flavour.

- Extruded Treats The least nutritious of any treat. The intense heat destroys any nutrition.

- Nutrieseal® Pure moisture extraction through refrigeration. Intense flavour & nutrition. Pasteurised for food safety